Industrial electric heaters fail most often for predictable reasons: uneven heat distribution, material mismatch, inadequate mechanical support, or designs that appear sound on paper but break down under real operating conditions.

Our manufacturing capabilities are engineered to eliminate these failure points by aligning heater design, materials, and assembly methods with how equipment is actually used in the field. This application-first mindset reflects the engineering principles that define why Creative Assemblies builds heaters differently.

Creative Assemblies specializes in manufacturing industrial electric heaters that perform consistently under continuous duty, elevated temperatures, and demanding airflow or process conditions.

Rather than relying on one-size-fits-all construction, our approach emphasizes precision, repeatability, and application-driven engineering supported by early-stage electric heater design consulting.

Precision Heater Construction Built for Real Operating Conditions

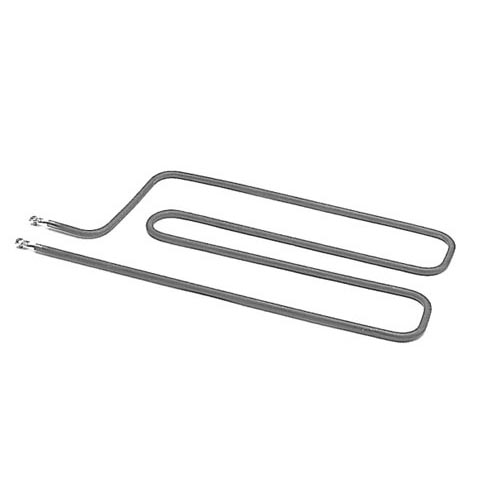

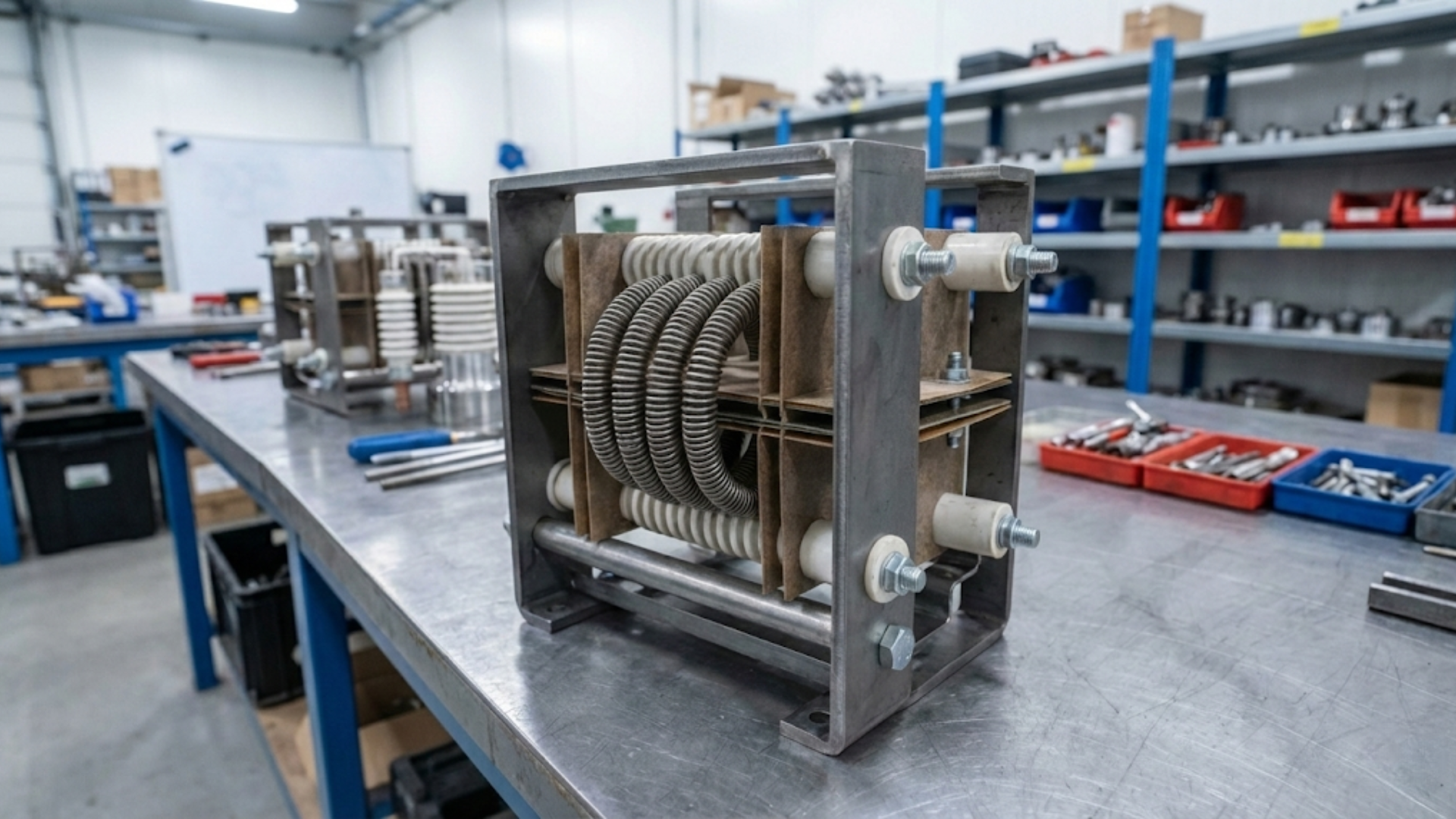

At the core of our manufacturing capabilities is open-coil electric heater technology. Resistance wire alloys are selected based on operating temperature, oxidation resistance, and long-term thermal stability. Coil winding geometry, spacing, and support layout are engineered to control watt density and airflow interaction, reducing hot spots, coil sag, and premature burnout.

Each coil assembly is designed to maintain consistent heat output across repeated thermal cycles. This level of precision is especially critical in air heaters and process heating systems commonly supported through open-coil electric air heater manufacturing, where airflow uniformity directly impacts system reliability and service life.

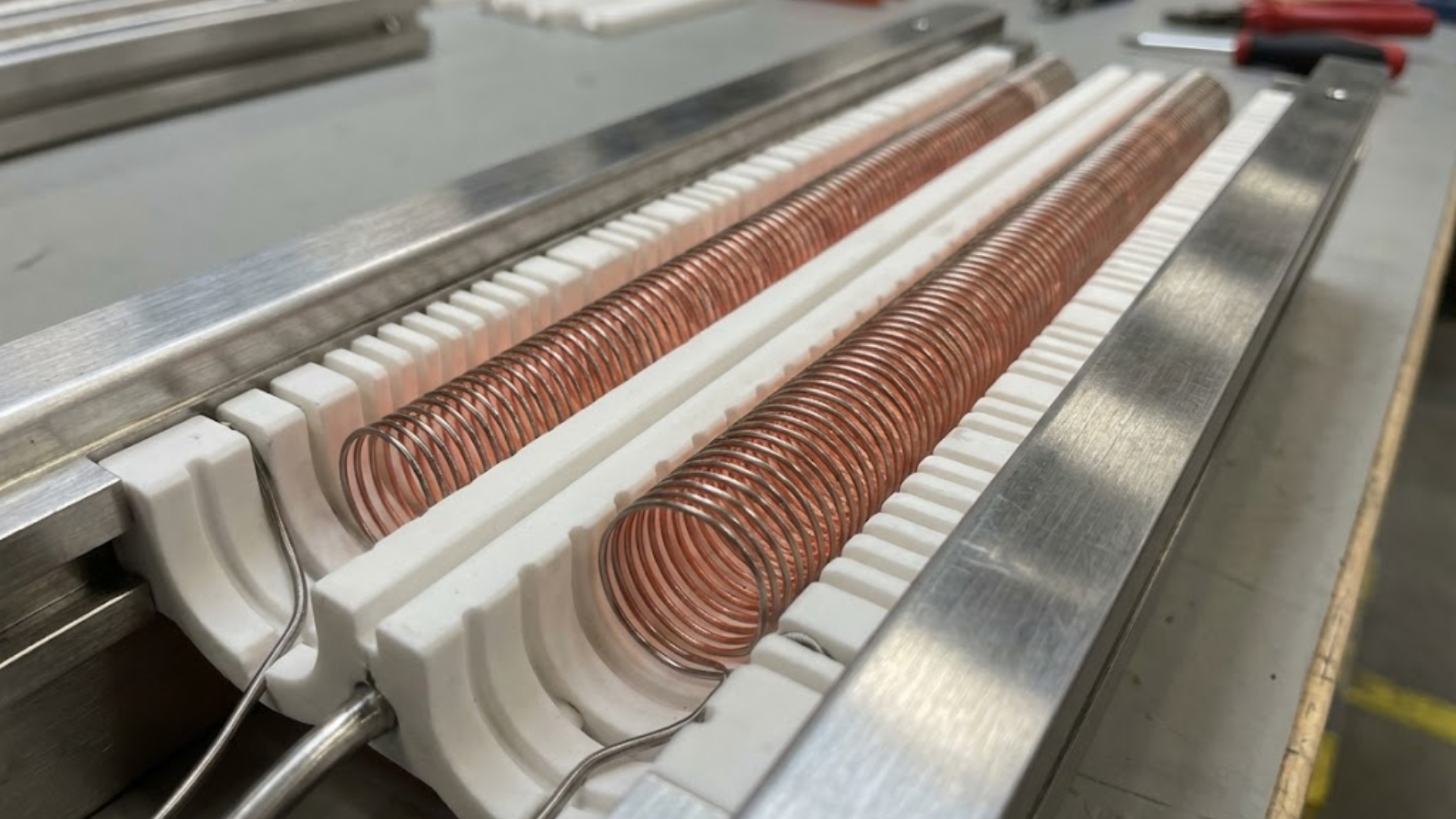

Integrated Assembly Using Proven Insulation and Support Systems

Heater performance depends as much on mechanical and electrical support as it does on the heating element itself. We integrate coils into ceramic insulators, mica supports, and metal frameworks selected for dielectric strength, thermal resistance, and mechanical stability.

Assemblies are designed to maintain electrical isolation while withstanding vibration, airflow forces, and thermal expansion. These construction principles are consistently applied across our custom electric heaters, where durability is prioritized over minimum specification compliance.

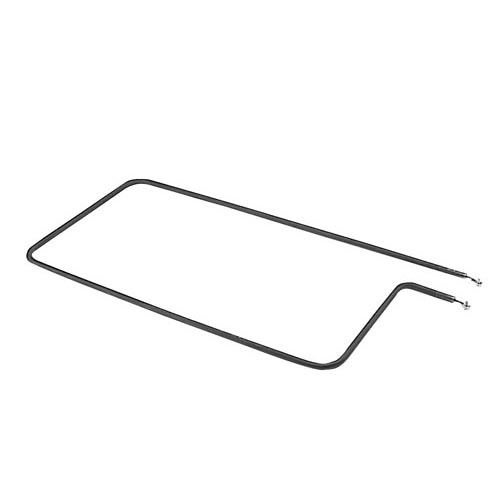

Our manufacturing operation supports both standard production and fully customized heater builds. We produce heaters across a wide range of voltages, wattages, and physical configurations, including single-phase and three-phase designs.

Customization options include mounting styles, terminal orientation, lead length, connection types, and frame geometry. This flexibility allows heaters to integrate cleanly into ducts, cabinets, ovens, and process equipment without forcing downstream compromises, an approach frequently required for OEM heater manufacturing support across the diverse industries we serve.

Material Selection Driven by Environment and Longevity

Material selection is never treated as an afterthought. Frame materials, insulation systems, and support hardware are chosen based on corrosion exposure, ambient temperature, airflow characteristics, and expected service life.

Stainless steel, aluminized steel, and specialty alloys are specified where required to balance durability, cost, and thermal performance. These decisions align with the long-term reliability standards that guide how we approach heater manufacturing.

Consistency and reliability are reinforced through controlled manufacturing processes and inspection checkpoints throughout assembly. Electrical resistance, insulation integrity, and mechanical alignment are verified before heaters leave the production floor.

Functional testing confirms that each heater meets performance and safety expectations before shipment. This disciplined quality approach mirrors the standards applied in heater repair services,

where restoring performance and extending service life are critical objectives.

Engineering Support That Improves Manufacturability

Our heater technologies are supported by engineering collaboration early in the project lifecycle. Design-for-manufacturability reviews help optimize coil geometry, support structures, and material choices before production begins.

Early involvement reduces redesign cycles, improves yield, and ensures heaters are not only manufacturable but reliable under real operating conditions. This engineering-led philosophy is a defining element of how Creative Assemblies supports industrial customers nationwide and is reinforced through ongoing insights shared on our technical blog.

Built for Durability, Not Just Specification Compliance

By combining disciplined manufacturing processes with application-focused heater design, Creative Assemblies delivers industrial electric heaters engineered for durability, consistency, and long-term performance rather than short-term specification compliance. Customers seeking application-specific solutions can further explore our heater technologies, engineering capabilities, and industry-specific solutions throughout the site.